Jan 2024

Gases and fumes in high-temperature processes?

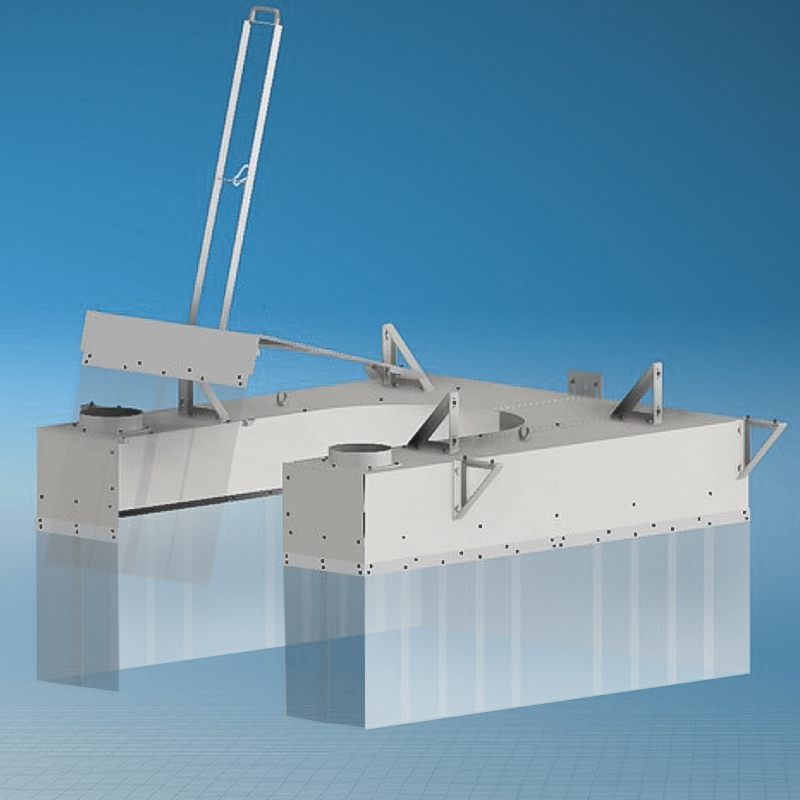

No danger with the Multi-slot Special Extractor Hood IFESHKT-06

For a global leader in extrusion blow molding technology, Fuchs Umwelttechnik designed and manufactured a completely customized special extraction hood.

The situation: At an extrusion blow molding machine, the plastic is melted in the extrusion system. Through an extrusion head, the plastic will be blown into a mold via a nozzle to give the plastic its final shape. During the high-temperature process, gases and fumes are generated, which have to be extracted by a suitable extraction system.

Using their know-how and experience, our engineers designed once again a well-thought-out, practice-oriented solution. With this 3- component extraction hood, mounted underneath the customer's support frame, the extrusion point is completely enclosed. The hood is designed with a practical and simple assembly/disassembly system consisting of, above all, PVC strip curtains as well as a removable cover with magnetic fasteners and a fall protection. In conjunction with a fan, all resulting emissions are extracted and led out of the workshop.